The goal of workflow automation is to create efficiencies that can lead to more capacity, lowered costs and increased profitability for your business. Konica Minolta provides workflow solutions that are tailored to your operation, using LEAN methodologies and tools to eliminate waste, decrease non-value added steps and reduce overall touch points.

Ask two people in the Graphic Communications space what an optimized workflow looks like, and you will get two different answers. That’s because businesses have different equipment, services, processes, labor skill sets, quality standards and opinions. Some consider workflow the process from job intake or estimation all the way out to delivery verification, while others just think of physical printer queue management and automation.

No matter your definition, starting with a Konica Minolta LEAN Workflow Assessment minimizes touch points and improves operational processing. We define and report on all relevant bottlenecks, areas of waste (including time, motion, materials and inventory costs) and non value-added steps. A detailed assessment provides you with the critical information needed to understand the ROI of making changes to your workflow. When changes call for the integration of existing systems into new advancements in production management solutions, we provide the perfect services.

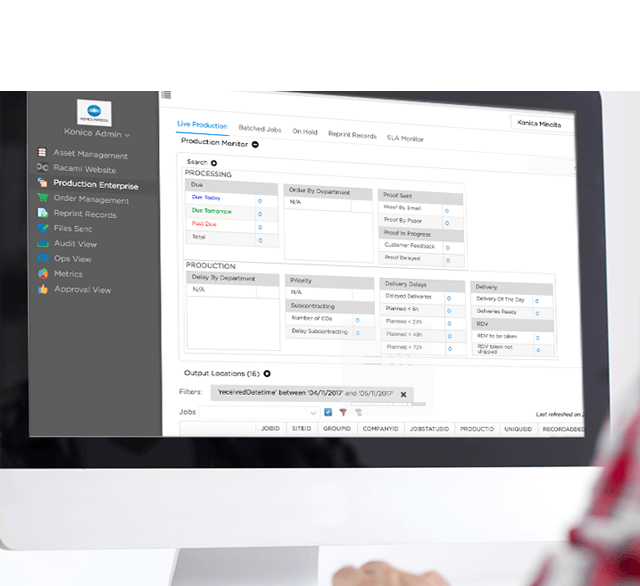

No production management environment is too large or too small. Konica Minolta’s production management solutions are fully scalable and provide both cloud and on-premise options to manage the flow of information, assets and work product through your production facility. Our solutions allow you to leverage existing investments and create workflows that meet your needs now – and into the future.