With the popularity of social media and other platforms these days, it would be easy to dismiss print materials, and to think that they’re not as popular, or in the case of marketing, as effective.

But in fact, the reality couldn’t be more different.

Today’s leading companies are embracing innovation and integrating digital technology with print to become more customer-centric. As COVID-19 has accelerated print trends that increase its relevance, moving from one-size-fits-all to customization and personalization, digital print is here to stay. Furthermore, it continues to accelerate in its adaptations to meet new and exciting uses for brands around the world.

Cross-channel opportunities are multiplying

While the digital label and packaging business today is about 40 percent digital, Smithers Future of Packaging Long-Term Strategic Forecasts to 2030 states that this will jump to 60 percent in the next ten years. That’s largely because of the cross-channel opportunities – tech-enabled interactive packaging and print marketing can now include links to social media, QR codes and interactive games.

You may have already seen some packaging boxes that enable mobile phone users and online users to connect to brands quickly and easily. Packaging and labels are now springboards to let customers connect to microsites and promotional offers, making these enhanced materials especially attractive to marketers, in addition to bringing unique customer information to the forefront.

Inline finishing produces completed packaging and embellished labels

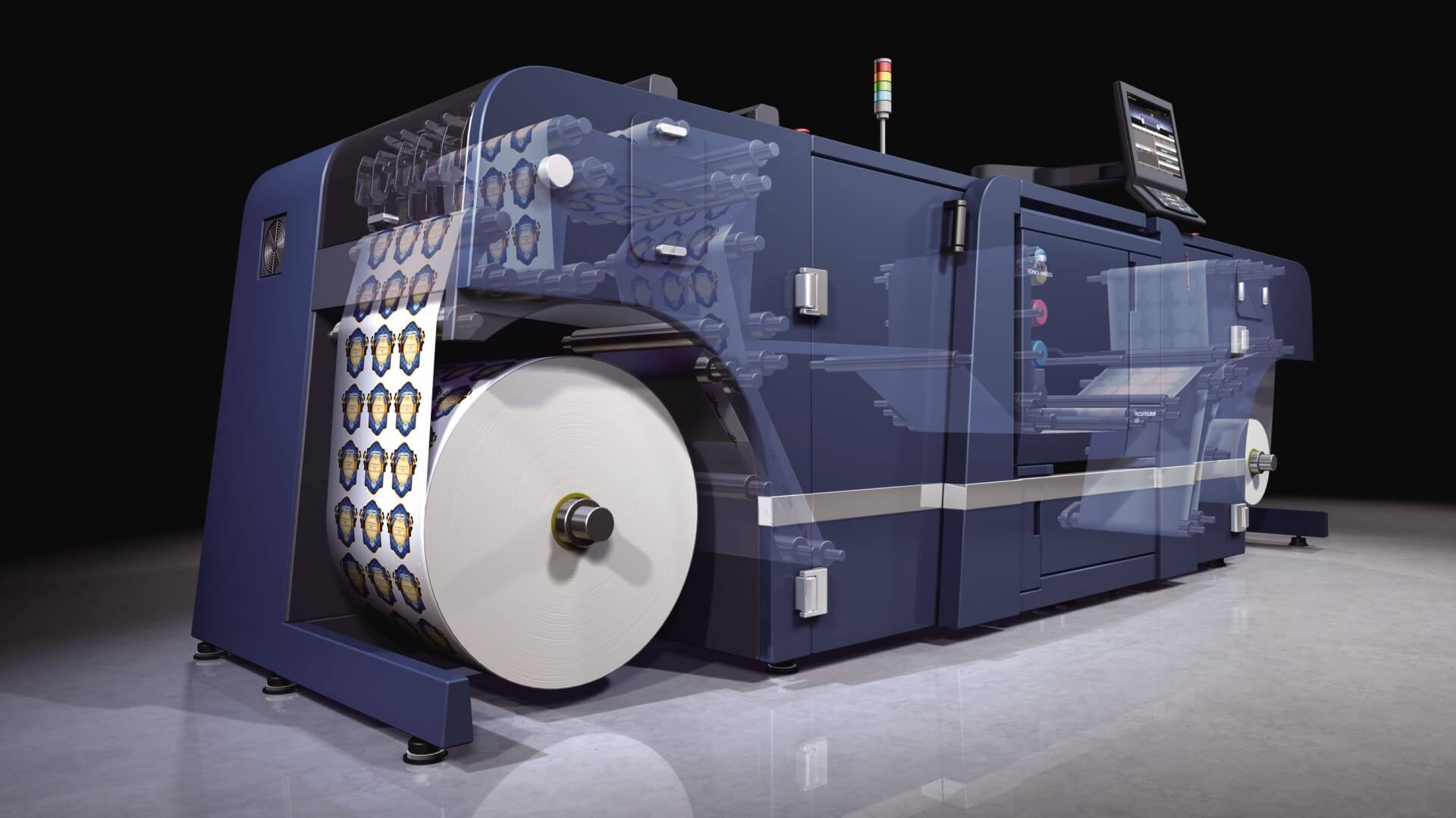

With a raft of new finishing options and software available at scale – and for short runs – the digital production print industry can offer customers finished output from a manufacturing perspective – meaning that all the finishing is automated in-line with the printed product. This is, and will continue to be, critically important from a labor perspective and will save customers a lot of time and money.

A few of the embellishments that are growing in popularity include laser die-cutting, foil stamping and digital varnishing techniques. And no wonder – studies show that packaging with specialty printing and enhancement delivers a 46 percent increase in quality perception. High-end packaging is moving from one-size-fits-all to customization and personalization, thanks to new digital technologies, and their use is growing at over 10 percent per year. Konica Minolta expects that the global label and packaging industry will be 60 percent digital by 2032.

This increased demand for aesthetic printing and packaging solutions is growing especially fast in end-use industries, such as food and beverage categories, and in pharmaceutical packaging. But a wide range of creative brands are putting new packaging technologies to use. According to a 2021 Markets and Markets report, the global packaging printing market is expected to grow from USD $352.1B in 2020 to USD $433.4B by 2025. That’s a CAGR of 4.2 percent in a five-year span.

Reducing waste and making packaging recyclable are fast-growing trends

The world’s leading production print companies are focused on CO2 reduction targets, with initiatives that include creating lighter-weight packaging, making packaging materials recyclable and embracing anti-plastic drives. There are concerted efforts being made across the industry to reduce waste, even on machine setups, because waste not only includes wasted prints, but also all the chemicals used in production printing.

Increased environmental awareness across brands and markets and the rising cost of raw materials are driving demand in the commercial and industrial printing sector to change the waste trajectory. Now the trend is to print the right stuff at the right time and at the right place, which enables more sustainable printing and packaging. Konica Minolta is proud to be among the 100 Most Sustainable Corporations in 2021, per Eco Vadis sustainability ratings.

Print is evolving to become more engaging and more profitable for customers

The ability to create digital embellishment, along with the ability to automate those embellishments for short or longer runs, and do things like wide-format printing, interactive labels and packaging – and produce these enhanced materials completely inline to intensify experiences for customers – all point to a bright future for print.

For more information about the digital transformation possibilities in label and package printing and our production printing equipment, please visit Konica Minolta online.