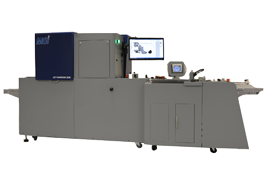

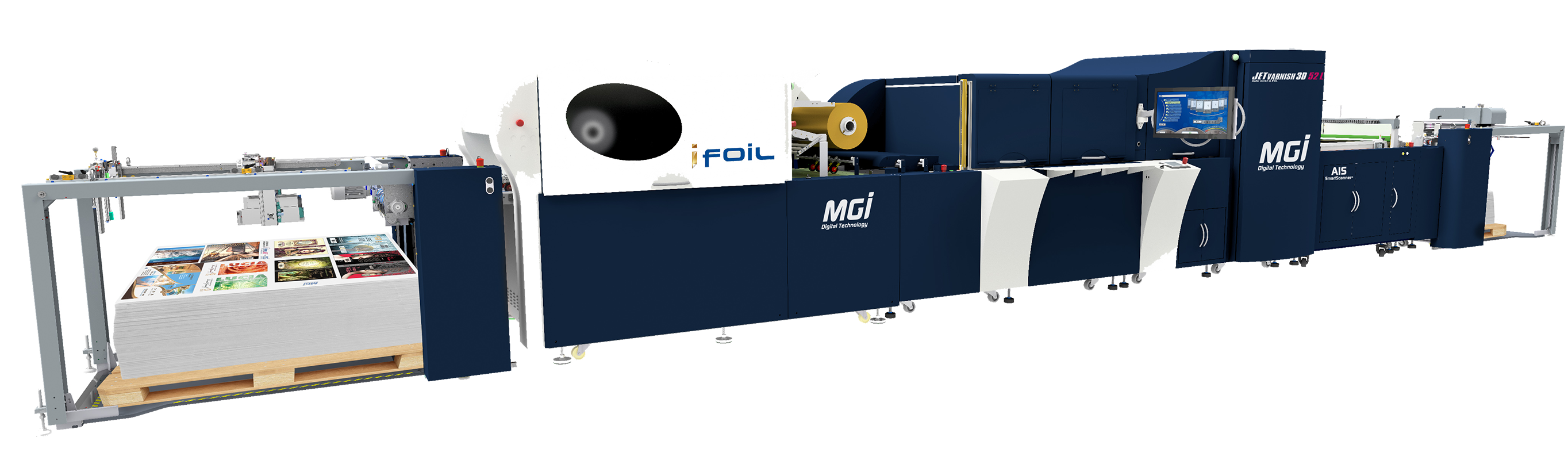

The JETvarnish 3DS can help you attract new prospects and realize lucrative market opportunities by providing customers with ultra-precise spot coating — handling digital or offset originals in long or short runs, even varying the thickness of your coating for attractive prints with tangible depth that increases communications impact.

KEY FEATURES

Ultra-precise digital inkjet spot coating

Coats up to 3,000 sheets per hour

Handles sizes from 8-1/2” x 11” to 14.33” x 40.15”

Creates eye-catching 3D tactile effects

- The ideal partner for both digital and offset presses — no expensive, time-consuming plates, screens or setups required beyond creating a graphic description file (5th layer mask)

- Konica Minolta’s Drop-on-Demand technology uses ultra-precise piezoelectric print heads to produce extremely thin lines (0.5mm) as well as wide uniform solid areas

- High-gloss coating formula delivers a gloss level of 99% (G.U.) — beyond the reach of traditional analog technology

- Standard AIS system uses Artificial Intelligence to create an automatic varnish and hot foil registration; it makes corrections and adjustments for any defects generated by the original offset or digital printing run

- Output rates of up to 3,000 sheets per hour in 30-micron coating thickness help you keep ahead of tight production deadlines

- Flat and varying degrees of coating can be created on the same sheet, adding visual and textured appeal for a premium high-end feel

- For large originals like book covers with multiple flaps, the JETvarnish 3DS can cover sheets up to 14.33” wide and 40.15” long

- Environmentally friendly operation optimizes coverage, eliminates the release of volatile solvents and ozone, reduces power consumption and minimizes noise

- Software Suite supplied for streamlining and facilitating production

- HubManager monitors ongoing jobs, adjusts the ARC system, manages print queue, creates job tickets and launches reprints

- Spot Varnish Editor lets the operator perform final touch-up of graphic files (5th layer mask) to speed production and increase throughput

- Production Cost Analyzer anticipates the exact quantity of varnish required and the cost of each production run to ensure accurate quotes and control profit margins

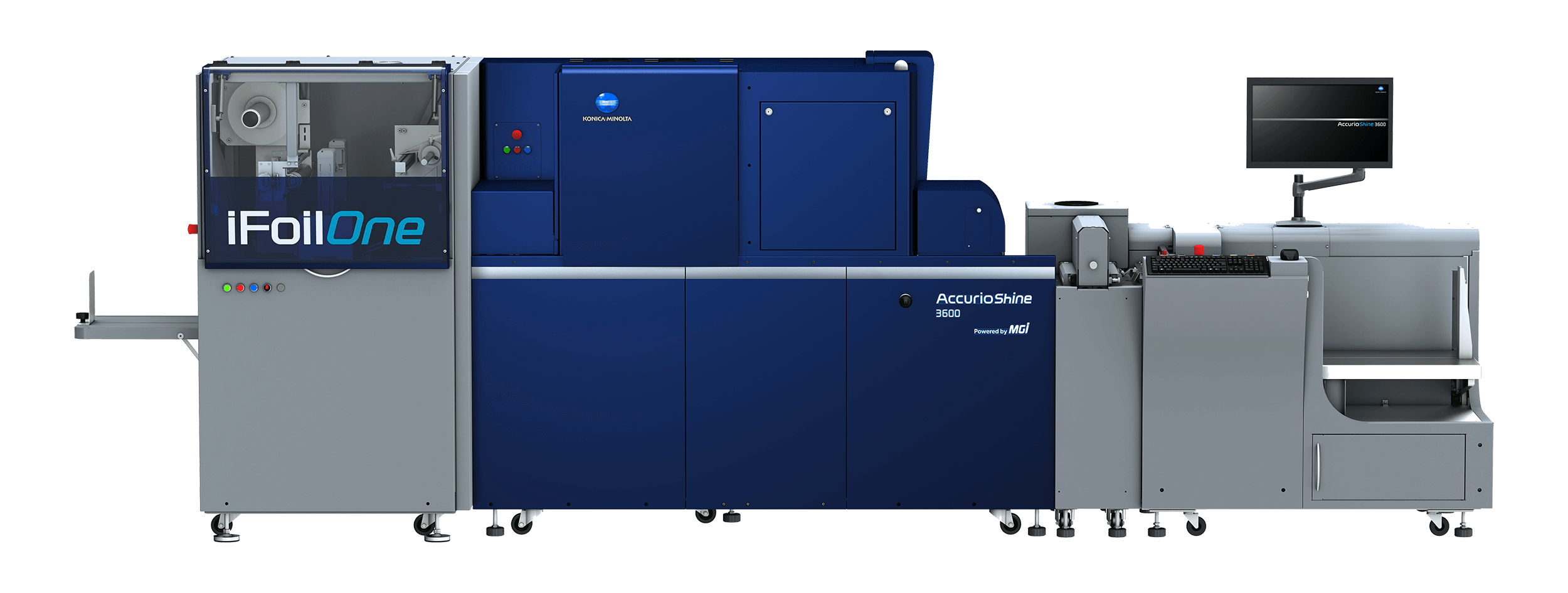

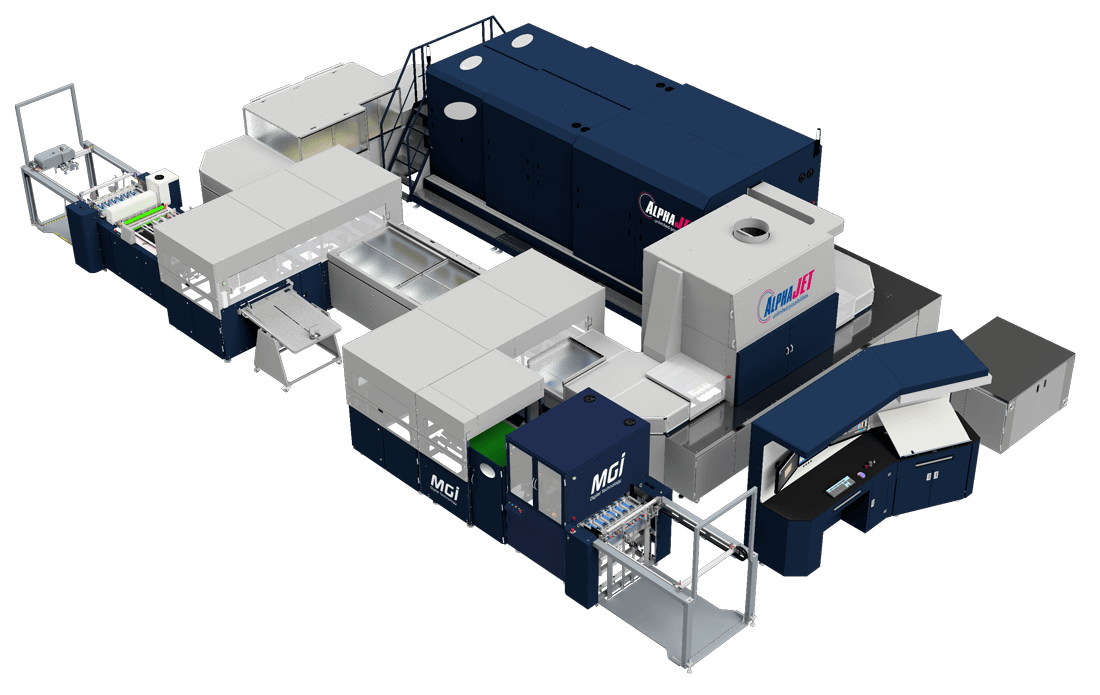

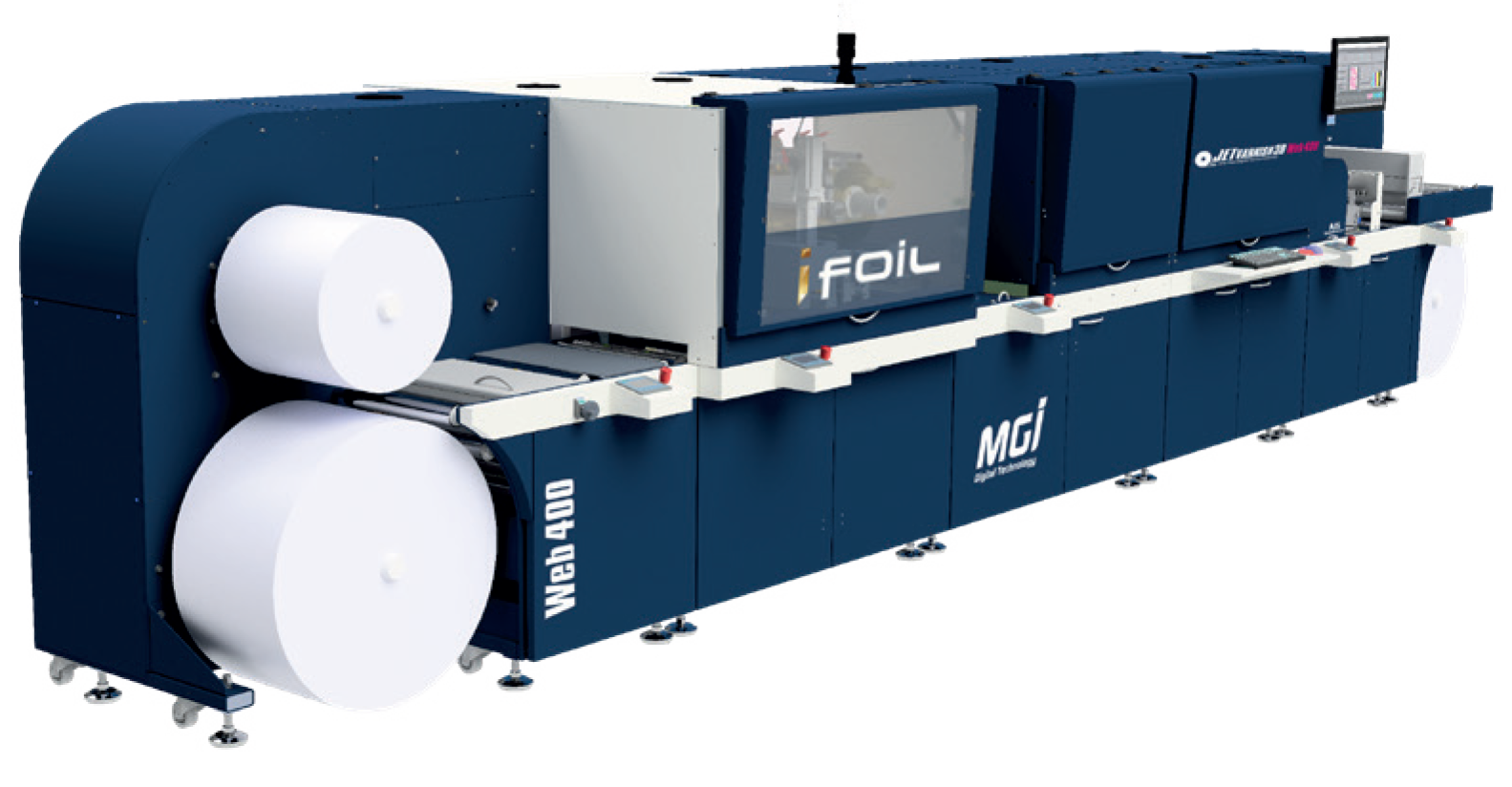

- The combination with the inline hot foiling module iFOIL S gives you an unlimited choice of different colors and glamorous effects