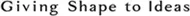

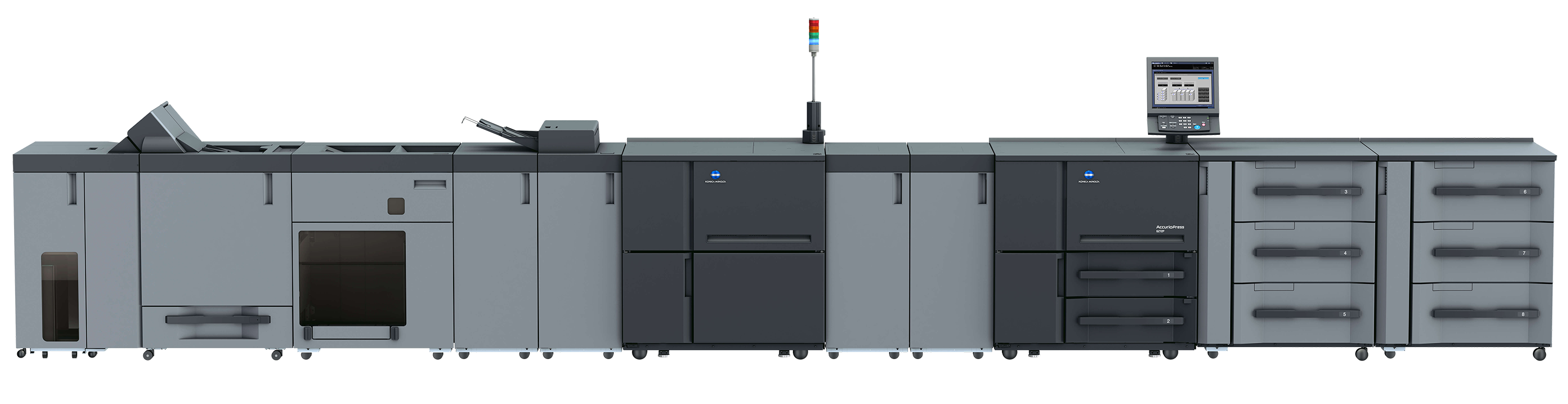

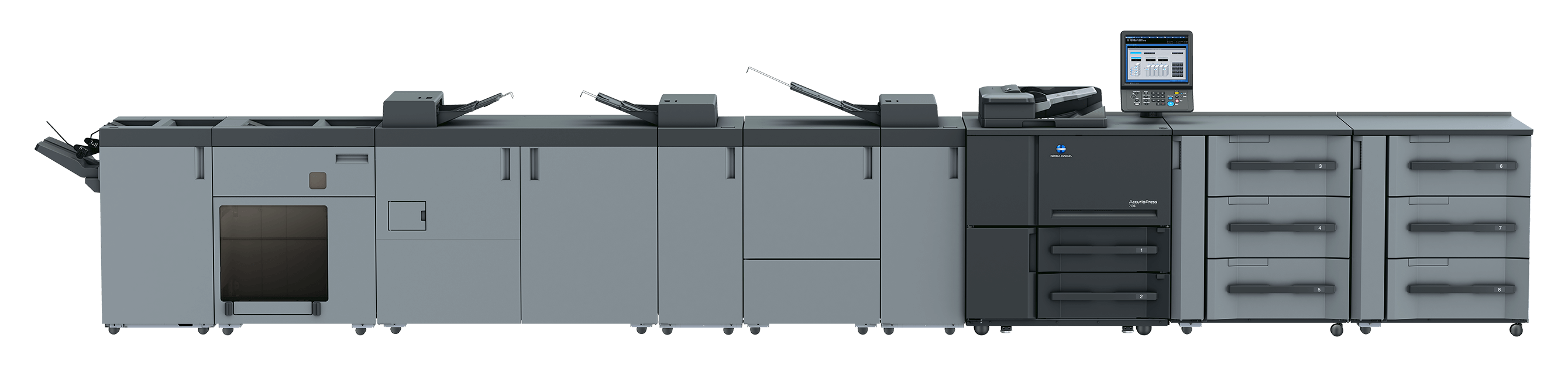

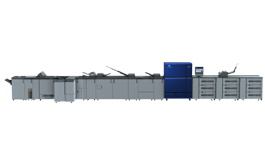

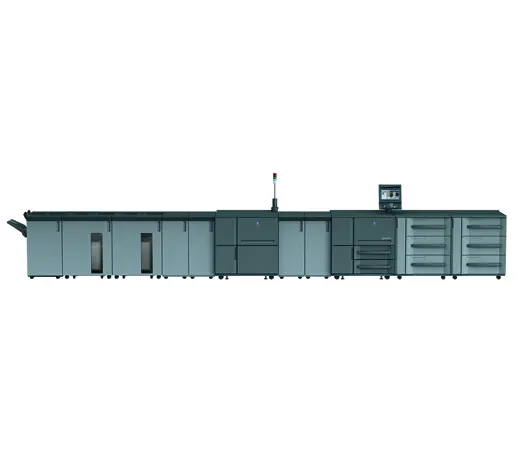

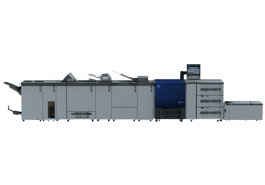

The AccurioPress 6136P digital printing press means business with up to 136 ppm print output, a monthly duty cycle of over three million impressions, and up to 18,000 sheet capacity. With real-time automated density and registration adjustments and powerful multiple inline finishing options, it gives you all the tools you need to grow your business.

KEY FEATURES

136 ppm B&W Print Output

3,240,000 Sheet Monthly Duty Cycle

Automated Closed-Loop Quality Management System

Powerful Inline Finishing Options

- Digital monochrome printer with industry-leading print output of 136ppm

- Fully automated, closed-loop quality management system provides consistent quality with automated density control and accurate front-to-back registration adjustments

- Large 15” color touch-screen display with superior visibility and operability, which greatly improves operation efficiency

- Advanced job management support for operators, includes Color Centro software, Job ticket/page editing and paper catalogue support, which simplifies output work and reduces labor costs

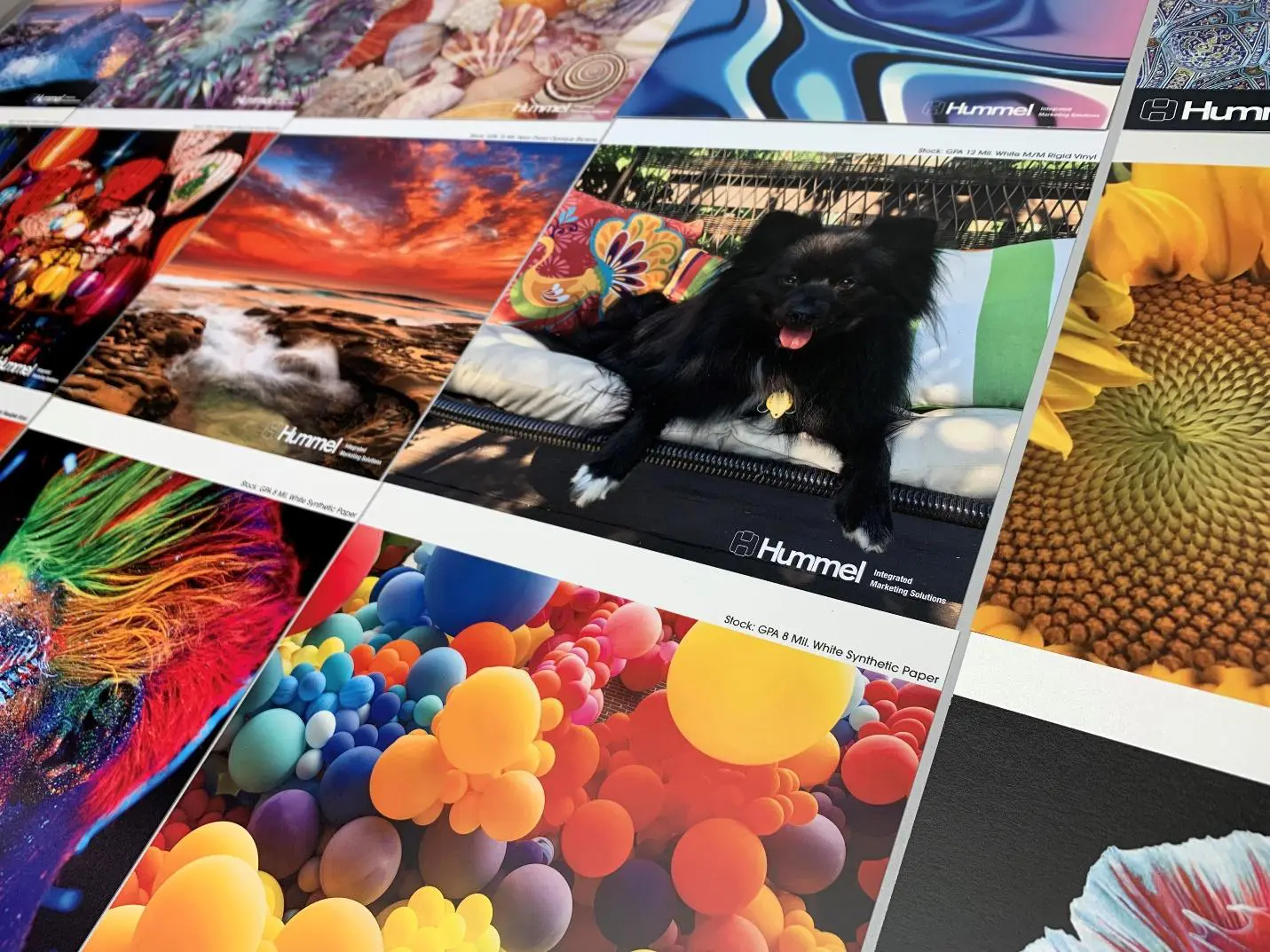

- 1200 x 1200 DPI resolution with 256 gray shades produces sharper text, denser black fills and smoother halftone images on the high-volume digital press

- High digital press production with 18,000-sheet max paper capacity for long runs with less reloading

- IQ-501 Intelligent Quality Optimizer performs automatic density correction and front-to-back registration prior to printing

- 100-Sheet Staple Finisher for 2-point stapling and sorting, with options for saddle-stitch 80-page booklet-making, 2/3-hole punching and post inserter options

- Perfect Binder unit produces bound books up to 600 pages with precision paper and cover alignment

- Multi-Folding Unit with six folding patterns (including Z-fold), 2/3-hole punch and post-insertion capabilities

- Plockmatic and Watkiss BookletMakers are available for full bleed, 3-sided trimmed booklets

- Large Capacity Stacker Unit handles up to 5,000-sheet output with rollaway trolley to move print output to offline finishing or distribution points

- The de-curling humidifier unit performs de-curling adjustment in real-time during printing without interruption. In addition, can be equipped with a humidification unit, enabling a hybrid de-curl system that uses both a mechanical system and humidification system

- Inline accessory offers multiple-hole die sets with selectable pins for the most common professional punch patterns, enables punching of a wide range of sheet sizes both on the long and the short edge of the sheet, double-punch capability for two-up sheet and includes the ability to punch tabs

- Roll feed system accessory provides on demand cut sheets for hours of uninterrupted run time, increasing throughput while lowering downtime, operator involvement and paper costs

- Custom-designed Konica Minolta Controller

USA

USA Global

Global